Home > Company News > Advantages of stamping molds

Company News

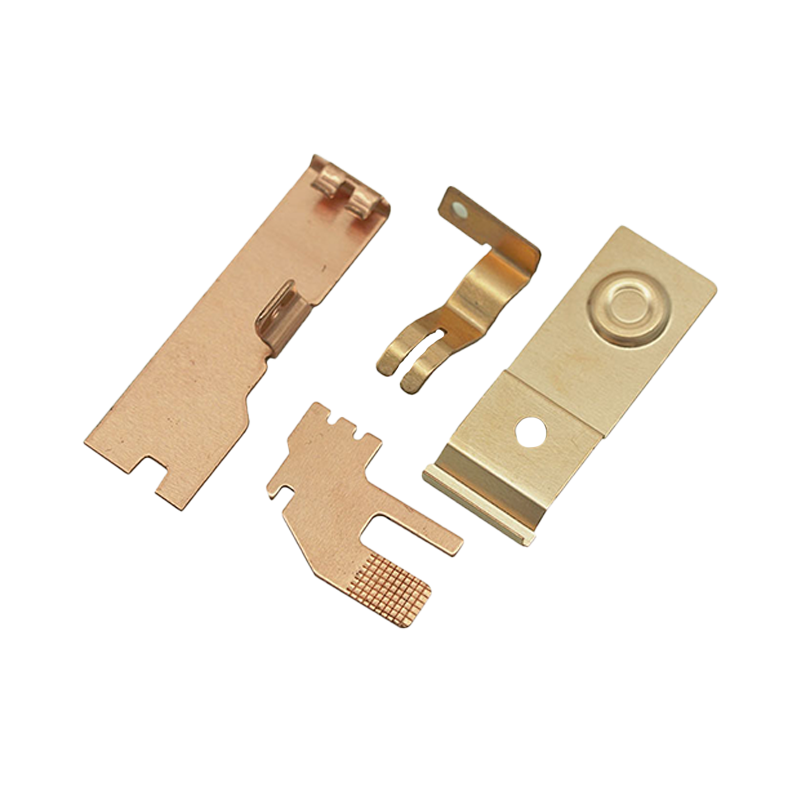

Stamping molds are a mechanical processing tool with many advantages. Firstly, stamping molds have efficient production capacity. By using automation equipment, large-scale and high-speed production can be achieved, greatly improving production efficiency. Secondly, stamping molds have high accuracy and stability. The stamping process is precisely controlled by the mold, which can ensure the consistency of product size and stability of quality, and meet the needs of precision components. In addition, stamping molds have high product quality. Due to the small deformation of the material during the stamping process, while ensuring product quality, it also reduces the scrap rate. At the same time, stamping molds also have lower costs. The one-time investment of stamping molds is relatively large, but their service life is longer, so they can be produced for a long time within a certain cycle, reducing production costs. Stamping molds also have a wide range of applications. Products of different shapes and sizes can be processed through different stamping molds, which have strong flexibility and adaptability. Overall, stamping molds have unique advantages in improving production efficiency, ensuring product quality, reducing costs, and increasing applicability, making important contributions to the development of the manufacturing industry.