Home > Company News > What are the commonly used processing materials for stamping parts

Company News

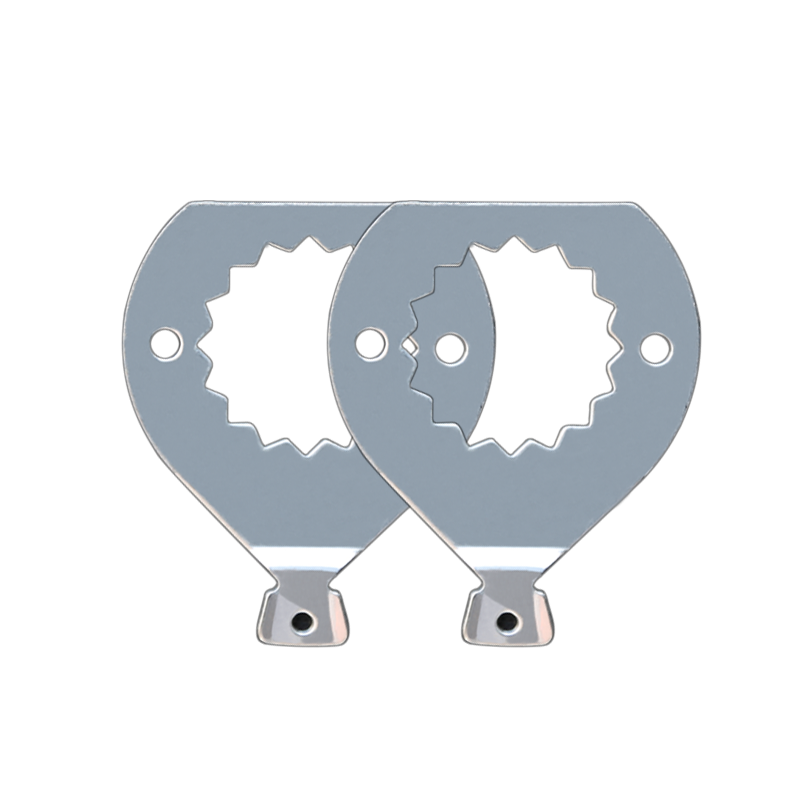

There are many types of commonly used processing materials for stamping parts, and I will introduce some of them below. Firstly, stainless steel is a commonly used stamping material with corrosion resistance, high strength, and good processing performance, commonly used in the manufacturing of automotive components, household appliances, and other products. Secondly, aluminum alloy is also a common stamping material with the characteristics of lightweight, corrosion resistance, and good conductivity, commonly used in the aerospace field and the manufacturing of electronic products. In addition, steel is one of the most widely used materials in stamping parts, including ordinary carbon steel and alloy steel, which have high strength, wear resistance, and strong weldability, and are widely used in industries such as automobiles, machinery, and construction. There is also copper alloy, which has good thermal conductivity and conductivity, and is commonly used in the manufacturing of electronic equipment and power systems. Finally, plastic materials, such as polypropylene, polyvinyl chloride, etc., have lower costs, good corrosion resistance, and insulation properties, and are commonly used in packaging, daily necessities, and other fields.

In the stamping process, selecting suitable materials is crucial for improving product performance and reducing costs. Different materials have different characteristics and advantages, suitable for different industrial fields and product applications. Therefore, when selecting materials, it is necessary to consider factors such as the product's usage environment, processing difficulty, and cost. In addition, attention needs to be paid to the availability and supply stability of materials to ensure the continuity and efficiency of production.

With the continuous development of technology and changes in demand, the material selection of stamping parts is also constantly innovating. Some new materials, such as high-strength steel, titanium alloys, and composite materials, are gradually being applied in the manufacturing of stamped parts, providing higher performance and wider application areas for products. Meanwhile, with the improvement of environmental awareness, the application of recyclable and degradable materials is gradually increasing to reduce their impact on the environment.

Overall, the commonly used processing materials for stamping parts include stainless steel, aluminum alloy, steel, copper alloy, and plastic. Choosing appropriate materials is crucial for the manufacturing and performance of stamping parts, and it is necessary to comprehensively consider factors such as the product's usage environment, processing difficulty, and cost. With the progress of technology and changes in demand, the application of new materials is also constantly developing, providing more choices and possibilities for the manufacturing of stamping parts. At the same time, the improvement of environmental awareness is also promoting the application of recyclable and degradable materials to reduce their impact on the environment.