How is the cost of injection molding calculated

Before we can understand the cost calculation method of injection molding, we need to understand that injection molding is a production method that is widely used to produce plastic parts of various shapes, sizes and structures. They are used in everything from medical devices to children's toys to automotive parts, so understanding their cost factors is critical for many in the industry. The cost calculation of injection molding involves many aspects. The first is the cost of raw materials, which is the single most important factor influencing the decision. The type, quality and price of raw materials are directly related to the cost of the final product. In addition, the selection of raw materials will also affect the energy consumption, production efficiency and product quality in the production process. This also determines that manufacturers need to conduct market research to select the most suitable and cost-effective raw material suppliers.

The cost calculation of injection molding involves many aspects. The first is the cost of raw materials, which is the single most important factor influencing the decision. The type, quality and price of raw materials are directly related to the cost of the final product. In addition, the selection of raw materials will also affect the energy consumption, production efficiency and product quality in the production process. This also determines that manufacturers need to conduct market research to select the most suitable and cost-effective raw material suppliers. Secondly, the process management is also an important link. Depending on the structure and use of the product, the injection molding process may vary greatly. From the mixing of raw materials, injection molding, cooling, to the cutting and assembly of materials, each step requires fine management and control. The level of fine control and efficiency of these steps will affect the cost and effectiveness of production.

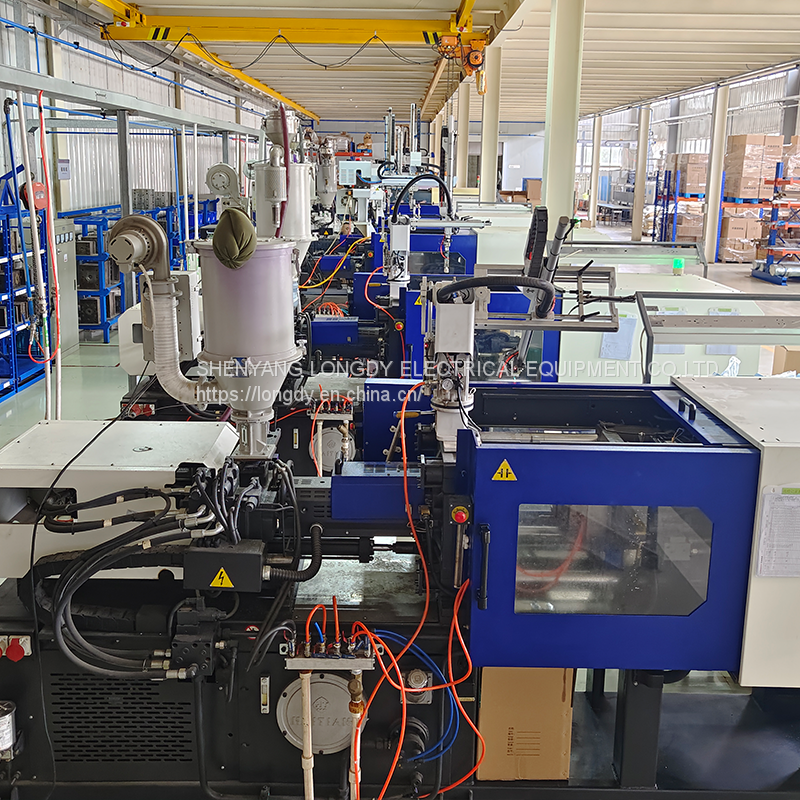

Secondly, the process management is also an important link. Depending on the structure and use of the product, the injection molding process may vary greatly. From the mixing of raw materials, injection molding, cooling, to the cutting and assembly of materials, each step requires fine management and control. The level of fine control and efficiency of these steps will affect the cost and effectiveness of production. Then, the investment of equipment is also a big expense. The purchase and maintenance of injection molding machines, molds and other related equipment will greatly affect the production cost and quality. Therefore, the purchase of efficient, durable and cost-effective equipment is an important issue for manufacturers to consider.

Then, the investment of equipment is also a big expense. The purchase and maintenance of injection molding machines, molds and other related equipment will greatly affect the production cost and quality. Therefore, the purchase of efficient, durable and cost-effective equipment is an important issue for manufacturers to consider. In addition, labor costs, energy consumption costs, operation and management costs also have an impact on the cost of injection molding. Therefore, we can see that the cost of injection molding is affected by a number of factors, in order to achieve the best economic benefits of production, manufacturers need to make wise decisions in each link, and continue to optimize the production process, in order to ensure product quality at the same time, as far as possible to reduce production costs.

In addition, labor costs, energy consumption costs, operation and management costs also have an impact on the cost of injection molding. Therefore, we can see that the cost of injection molding is affected by a number of factors, in order to achieve the best economic benefits of production, manufacturers need to make wise decisions in each link, and continue to optimize the production process, in order to ensure product quality at the same time, as far as possible to reduce production costs.

Recently Posted

-

Discover the wonderful world of microswitches

November 24, 2025In the vast ocean of modern technology, there are countless fascinating tiny wonders. Although they are inconspicuous, they play a Read More

Read More -

Why use high voltage auxiliary switches for triplex mechanisms in power equipment? In-depth analysis

November 24, 2025In the complex operation system of power equipment, the three-position mechanism plays a crucial role. Among them, the application Read More

Read More -

Several golden rules for selecting materials in stamping processing

August 5, 2024In stamping processing, the selection of materials is crucial, because it not only affects the quality and precision of the parts, Read More

Read More -

How to improve the precision and efficiency of CNC machining?

August 5, 2024In modern manufacturing, CNC technology has become the core force in the production of complex parts and components with its high Read More

Read More