Why use high voltage auxiliary switches for triplex mechanisms in power equipment? In-depth analysis

In the complex operation system of power equipment, the three-position mechanism plays a crucial role. Among them, the application of high-voltage auxiliary switches has profound significance and irreplaceable value. So, why does the three-position mechanism in the power equipment use high-voltage auxiliary switch? This is worth our in-depth investigation of the problem.

First of all, we need to understand the basic working principle and functional characteristics of the three-position mechanism in power equipment. The three-position mechanism usually has three different working positions, which can achieve a variety of electrical connection state switching to meet the needs of the power system under different working conditions. For example, in substations and other places, the three-position mechanism can flexibly control the on-off of the circuit, switch different power supplies or loads. However, such complex operations and frequent switching processes place extremely high demands on the accuracy and reliability of the electrical control.

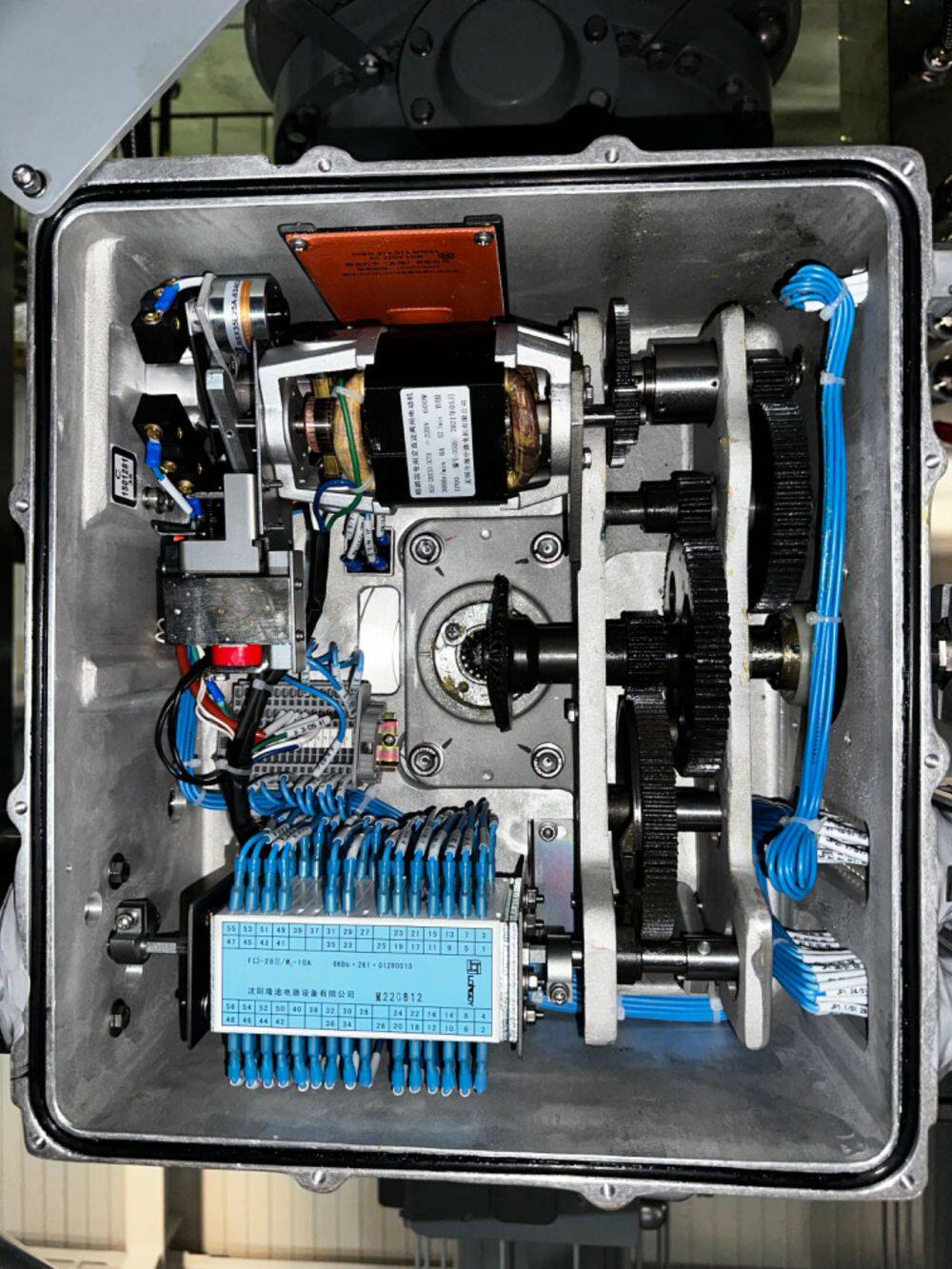

This leads to the importance of high voltage auxiliary switches. The high voltage auxiliary switch plays a key role as an auxiliary control in the triplex mechanism in electrical equipment. It can work stably under high voltage environment and accurately sense and transmit the working status information of the three-position mechanism. When the three-position mechanism is switching positions, the high-voltage auxiliary switch can send out signals in time to notify the relevant control system. In this way, the control system can accurately adjust and control the operation of other electrical equipment according to these accurate signals, ensuring the coordinated operation of the entire power system. For example, in a large substation, every action of the three-position mechanism may affect the power supply of multiple circuits, and the precise signals transmitted by the high-voltage auxiliary switches are like a ‘baton’, guiding the various equipment to work in an orderly manner, avoiding misoperation or failure caused by inaccurate information.

Secondly, from the safety point of view, the use of high-voltage auxiliary switches is also crucial. In electric power equipment, there are huge safety risks in the high-voltage environment. The lack of effective monitoring and control means during the operation of the triplex mechanism can easily lead to electrical accidents, such as short circuits and overvoltages. The high-voltage auxiliary switch can monitor the working status of the three-position mechanism in real time, and once abnormalities are found, it can quickly cut off the relevant circuits or send out alarm signals. This is like installing a ‘safety line of defence’ for power equipment, effectively guaranteeing the safety of equipment and personnel. For example, in some bad weather conditions, power equipment is more likely to fail, high-voltage auxiliary switch can detect the abnormalities of the three-position mechanism in a timely manner, to prevent the further expansion of the accident, to ensure the stable operation of the power system.

Furthermore, the high-voltage auxiliary switch also has the role of improving the operational efficiency of power equipment. In the modern power system, there are more and more requirements for the efficiency of energy use and equipment operation. The three-position mechanism with the high-voltage auxiliary switch can achieve more accurate control and fast switching operation. Compared with traditional control methods, this combination can reduce unnecessary energy loss and time waste. For example, in some of the frequent need for circuit switching occasions, the high-voltage auxiliary switch can quickly respond to the action of the three-position mechanism, so that the switching process is more rapid and smooth, thus improving the operational efficiency of the entire power system.

In addition, with the continuous development and progress of power technology, the working environment and operational requirements of power equipment are becoming more and more complex. In this case, the reliability and adaptability of the high-voltage auxiliary switch is particularly important. It can adapt to different high voltage environments, temperature changes and electromagnetic interference and other unfavourable factors, and always maintain stable working performance. This enables the triplex mechanism to rely on the high-voltage auxiliary switch to achieve reliable control and operation in different power application scenarios.

In summary, the use of high-voltage auxiliary switches for triplex mechanisms in electric power equipment is designed to meet the high requirements of electric power systems for control accuracy, safety and operational efficiency. High-voltage auxiliary switches have become an indispensable and important part of the triplex mechanism by virtue of their unique functions and advantages. In the future development of electric power, with the continuous innovation of technology and application requirements, the role of high-voltage auxiliary switches in electric power equipment will be more prominent, in order to ensure the stable and efficient operation of the power system to play a greater role.

Recently Posted

-

Discover the wonderful world of microswitches

November 24, 2025In the vast ocean of modern technology, there are countless fascinating tiny wonders. Although they are inconspicuous, they play a Read More

Read More -

Several golden rules for selecting materials in stamping processing

August 5, 2024In stamping processing, the selection of materials is crucial, because it not only affects the quality and precision of the parts, Read More

Read More -

How to improve the precision and efficiency of CNC machining?

August 5, 2024In modern manufacturing, CNC technology has become the core force in the production of complex parts and components with its high Read More

Read More -

Reveal the core material of appliance parts stamping processing

August 2, 2024Stamping and processing technology is an integral part of the appliance manufacturing industry. It involves the use of molds and p Read More

Read More