Home > Company News > What are the common raw materials used in stamping process

Company News

Stamping is a common metalworking technique widely used in the manufacturing sector. By utilizing the high pressure action of a stamping press, sheet metal is placed in a punch die to deform or fracture it, ultimately achieving the desired shape and size. The raw material selected for the stamping process plays a critical role in the quality and performance of the final product. The purpose of this article is to introduce common raw materials used in stamping processes and provide detailed and comprehensive information.

carbon steel

Carbon steel is one of the most widely used materials in stamping. Its main components are carbon and iron, usually with small amounts of other elements. Carbon steel has good workability, weldability and mechanical properties, and therefore has a wide range of applications in industries such as automotive, home appliances, construction and machinery. Depending on the carbon content, carbon steel can be categorized into low carbon steel, medium carbon steel and high carbon steel. Carbon steel with different carbon content has different hardness and strength, and you can choose the suitable carbon steel material for stamping according to your specific needs.

stainless steels

Stainless steel is a highly corrosion-resistant steel that is often used in the production of products that require corrosion resistance. The material has high strength and hardness and is easy to process and decorate. Depending on its composition, stainless steel can be categorized into austenitic, ferritic and martensitic stainless steels. Each type of stainless steel has different chemical compositions and mechanical properties and is suitable for a variety of different stamping needs. Stainless steel is widely used in the manufacture of kitchenware, sanitary ware, electronic products and chemical equipment.

aluminum

Aluminum alloy is a very important metal material with low density, high strength and good workability, which makes it widely used in industries such as aerospace, transportation, electronics and construction. Not only that, aluminum alloys also have excellent corrosion resistance and thermal conductivity. The strength and hardness of aluminum alloys can be further improved by means of alloying and heat treatment to meet the requirements of stamping and machining in various fields. Common types of aluminum alloys include aluminum-copper alloys, aluminum-manganese alloys and aluminum-silicon alloys.

Galvanized steel sheet

Hot-dip galvanized steel sheet is a steel sheet that has been hot-dip galvanized with a protective layer of zinc attached to its outer surface, which can effectively prevent the steel from being eroded by oxidation and corrosion. Therefore, hot-dip galvanized steel sheets are widely used in outdoor product manufacturing, building structures and automotive parts, etc., which can improve the weather resistance and corrosion resistance of products.

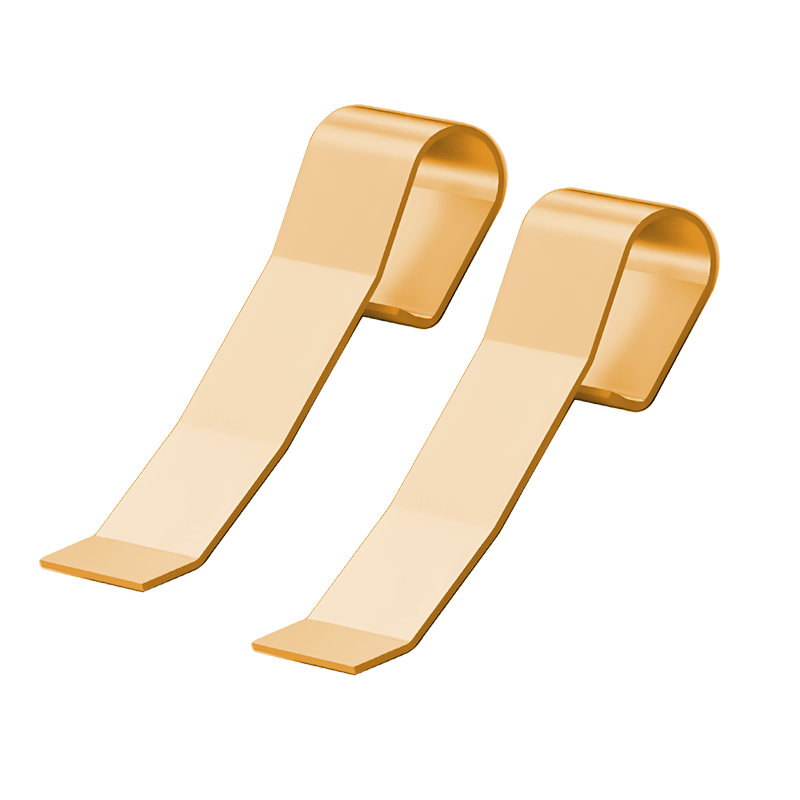

copper material

Copper is a metallic material with excellent electrical and thermal conductivity and is widely used in the manufacture of electronic equipment, electrical equipment and refrigeration equipment. It is very malleable and machinable, making it ideal for stamping. At the same time, copper has excellent corrosion resistance and remains stable for a long time under various environmental conditions.

To summarize the above, commonly used materials for stamping processing include carbon steel, stainless steel, aluminum alloy, galvanized steel and copper. Each material has unique characteristics and scope of application, and enterprises should choose suitable raw materials for stamping processing according to specific product requirements. Through reasonable selection and processing of raw materials, product quality and performance can be improved to meet market demand and realize the sustainable development of enterprises.