Home > Company News > What is the stamping manufacturing process

Company News

Stamped manufacturing is a common metalworking method used to form a desired part by applying multiple presses and shearing the sheet metal. This manufacturing process involves multiple steps and operations, going through a rigorous process from design to finished product.

First, the first step in press manufacturing is design. During the design phase, engineers draw up the appropriate CAD (computer-aided design) files based on the required part functions and specifications. The CAD file guides the subsequent manufacturing process and ensures that the resulting part meets the requirements.

The next step is the making of the tooling. The die is the heart of press manufacturing and determines the shape and size of the resulting part. Craftsmen use CNC machines and other machining equipment to create the dies, using high-precision cutting methods to ensure the quality and accuracy of the dies.

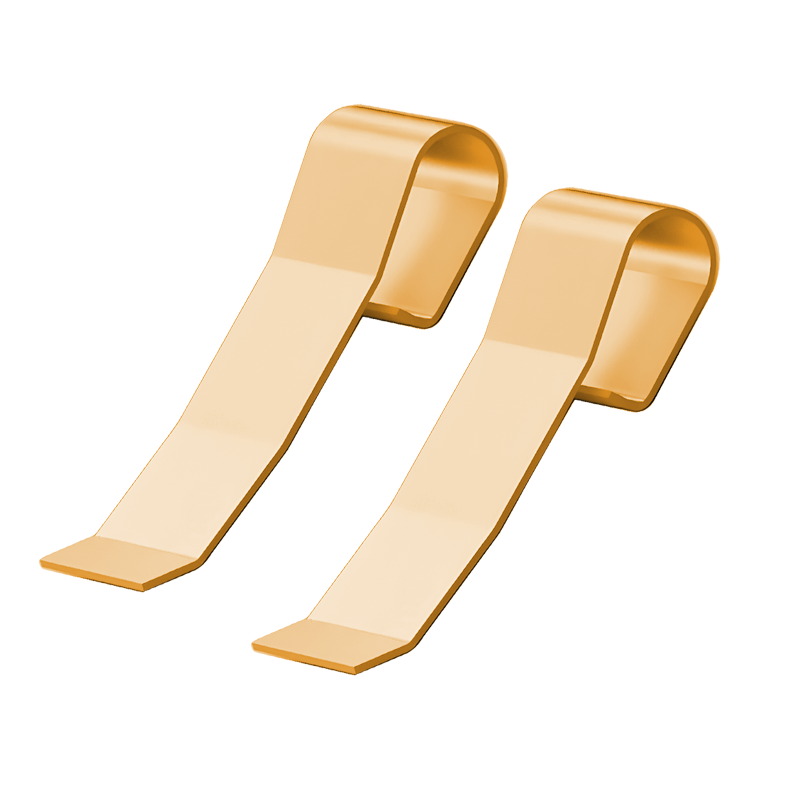

Once the die is made, the actual stamping and manufacturing begins. This process involves selecting the material, cutting and forming. First, the operator selects the appropriate sheet metal and cuts it according to the CAD file. The sheet metal is then placed into the press and the dies are mounted on the top and bottom of the press. The press applies pressure and interacts the tabs and grooves on the die by the movement of the upper and lower presses to shear and shape the sheet metal.

During the stamping manufacturing process, multiple operations and multiple stamping processes may be required to progressively complete the desired part shape. This requires operators to be skilled and experienced in stamping. They need to adjust press parameters, change dies, and ensure that the quality and dimensions of the part meet the requirements through constant test presses and inspections.

Once all the stamping processes are completed, the required parts are obtained. These parts may require further machining and processing such as welding, polishing and coating to achieve the final product requirements. Eventually, these parts will be assembled together to form the final product.

The process of stamping manufacturing involves several steps, each requiring precise operation and strict control. An error or non-conforming product in any one of these steps can lead to the failure of the entire manufacturing process. Therefore, stamping manufacturing requires a high degree of expertise and quality management.

With press manufacturing, high volume parts can be produced in an efficient, precise and economical manner. This manufacturing method is widely used in industries such as automotive, electronics, home appliances and aerospace, and provides important support for modern industrial production.