Home > Company News > How to choose the right injection molding parts manufacturer

Company News

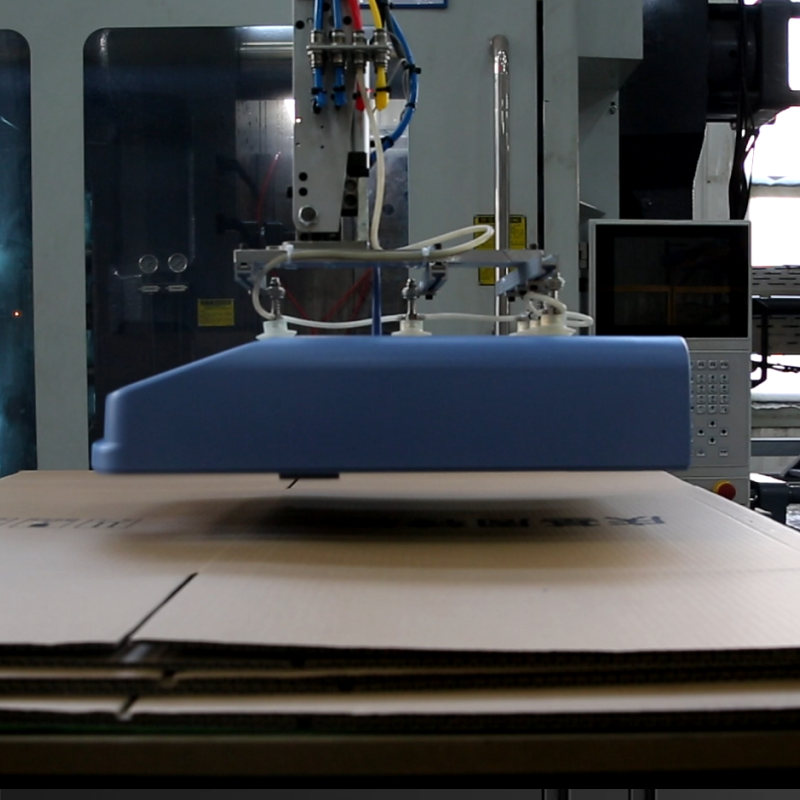

There are some important factors to consider before choosing a suitable injection molded parts manufacturer, as this decision will directly affect the company's production and market competitiveness. The following are the key factors to consider when choosing an injection molded parts manufacturer.The first thing you need to consider is the technical capability and experience of the factory. You need to look for a manufacturer that has enough experience and expertise to produce high-quality injection molded parts that meet your specific needs. In order to assess technical capabilities, you can ask the manufacturer if they have a high level of engineers and technicians, and check the modern production equipment they have, as well as their quality control and testing processes.

Then, the size and capacity of the factory need to be considered. To produce high quality injection molded parts, you need advanced production equipment and standardized production processes. Therefore, factories that are large and have high production capacity are more likely to produce large quantities of high quality products. In addition, these factories are also able to produce orders faster and meet urgent demands.

The third point is that you need to consider the reputation and credibility of the manufacturer. When selecting a manufacturer, knowing their history and customer feedback can help you assess their reputation more accurately. Check the manufacturer's customer reviews and refer to the experiences and opinions of other businesses to confirm that the manufacturer is reliable and trustworthy.

The fourth point is that cost needs to be considered. When looking for a manufacturer of injection molded parts, while quality and reliable service are both important, it does not mean that you have to bear high costs. You should compare the quotes offered by different manufacturers, and do not sacrifice quality for low prices. Instead, you should choose a manufacturer that takes quality, service and total cost into account.

Finally, consider the location and origin of the manufacturer. If the injection molded part manufacturer is in your local area, then you can more easily manage and supervise the production process, reducing transportation costs and time. In addition, if you need to use a specific material in your product, it will be more advantageous to find a local factory that produces that material.

Considering the above points and comparing them, Shenyang Londy is a more suitable injection molding parts manufacturer to improve production efficiency and product quality.